Static Control for High Speed Converting

SUMMARY:

Electrostatic charges on paper, film, fabric, and other non-conductive materials reduce processing efficiency and creates safety hazards.

ElectroStatics Inc. (electrostatics.com) a leader in static control and manufacturer of a variety of static control or static eliminator products and web cleaning equipment for the high speed converting industry has prepared this booklet. It will help familiarize you with the causes of and problems relating to static electricity in the converting environment and how these problems can be solved.

The first portion of this booklet will help clarify what static electricity is, as well as define some of the terminology important to understanding and controlling static electricity in the converting industry today.

The final sections of the booklet are dedicated to specific static related problems commonly found within the converting environment, as well as specific product recommendations for your individual needs.

CONTENTS

STATIC ELECTRICITY

CAUSES

CONDUCTIVITY

GROUNDING

IONIZATION

ELECTROSTATIC FIELD

HIGH SPEED CONVERTING

SUMMARY

STATIC NEUTRALIZING

BAR

STATIC ELIMINATOR

STATIC ELECTRICITY

What is static electricity? Static electricity denotes or pertains to electricity at rest.

How simple and yet inadequate this definition is of a phenomenon that creates defects which costs industry millions of dollars per year. A clearer understanding of static electricity can be gained by explaining lightning. Static electricity is generated by the transfer of charge from cloud to cloud as warm air is caused to rise at a rapid rate. The friction between air masses transfers charges from cloud to cloud, increasing an electrical potential voltage between clouds. Since the clouds are isolated and have no connection to the out-side world, the voltage between the clouds rises to the point where it is high enough to cause the air to ionize between the clouds, in this case air, becomes conductive because ionized air will conduct electricity when a sufficient voltage difference is reached. Then, a lightning discharge is created to equalize the voltage potential between clouds. For a brief instant the lightning flashes, static electricity in no longer at rest and tremendous energies are discharged along the shortest path.

What causes static electricity? How do we eliminate or at least control it? Let's examine it further, as it applies to sheet and web handling, especially high speed converting.

CAUSES

Static electricity is generated by disturbing the electrical balance of relativity non-conductive insulators such as plastic and paper. All matter is composed of atoms. A balanced atom contains positive charges that are present in the nucleus of the atom. An equal amount of negative charges orbits this nucleus in the form of electrons. Normally both charges are equal. Therefore the overall charge of a balanced atom is zero.

However, should this configuration be altered and several electrons removed from this atom, there will be a positive charge in the nucleus and a deficiency of electrons, which gives an overall charge in the positive direction. Conversely, if extra electrons are added, an overall negative charge will result because there will be an excess of electrons and the net charge is now negative.

Recognizing the above, when two surfaces are rubbed together, a transfer of charges takes place between these two surfaces. The friction causes electroncs to flow from one surface to the other, simultaneously creating one positive surface and one negative surface.

Balanced Atom

CONDUCTIVITY

The conductivity of material is extremely important when working with static electricity.

A non-conductor can be charged by induction by exposure to an electrostatic field that is present on a surface charged with static electricity. This is extremely important in areas where small charges of static electricity can create havoc, such as in the handling of plastic or paper sheet or webs. The ability of semi-conductive materials, such as paper, or non-conductive plastics to surrender electrons is relatively easy. Transfer of charges can occur by friction, the action of separation, heat or pressure.

A conductor can also be charged by induction, if it is isolated. For example, laying a piece of copper or aluminum on top of a piece of Plexiglas creates an isolated conductor. Rubbing the bottom surface of the Plexiglas under the copper will generate an extremely high voltage on the conductor through induction. It is impossible to charge a conductor which is grounded. The charges absorbed by the conductor will drain to ground.

The same condition will also charge an insulator that is isolated. It is useless to attach a ground to an insulator. Induction will cause a voltage on the insulator which cannot be drained to ground because electrons cannot move over an isolative surface. Thus, if processing non-conductive materials, static electricity cannot be drained from them simply by grounding them. This means that as non-conductive material passes over grounded rollers, static electricity cannot be drained from it.

GROUNDING

Grounding of plant machinery and related equipment is critical. Besides the safety factor, a grounded machine will help drain off extremely high charges of static electricity from partial conductors. However, grounding is only an aid to reducing problems with static electricity. It is not the total solution. Non conductive materials can not be grounded.

For example, grounding a web handling roller will not drain off static electricity from the isolative material. The conductivity of paper, cloth and many plastics is so low the electricity cannot flow to ground, therefore, static electricity remains. To solve this problem, ionization must be utilized.

IONIZATION

Another practical method of controlling static electricity build up is by ionization. It is important to understand that static electricity cannot be entirely eliminated. In fact, the terminology, "static eliminators", is definitely misleading.

Static eliminators are really ionizing units that produce both positive and negative ions to be attracted by the unbalanced material so that neutralization does occur. (For example, a charged piece of ionization equipment (static neutralizer).) However, it does not permanently eliminate the static electricity because, if the material is again rubbed after being neutralized, static electricity will be generated.

In order to gain the most benefit from static neutralizing equipment, it is important to understand how they operate and how they accomplish the means of neutralization. Most electrical neutralizers are constructed by placing a high voltage on a sharp point in close proximity to a grounded shield or casing. As the high voltage alternating current pulses through the 50 or 60 cycle operation, the air immediately at the sharp points is actually broken down by corona discharge and, therefore, both positive and negative ions are generated. Half of the cycle is utilized to generate negative ions. When operation occurs at 60 hertz, the polarity of ionization changes every 1/120 of a second.

If the material being neutralized is charged positive, it will immediately absorb negative ions from the static neutralizer and repel the positive ions into space. When the material becomes neutralized, there is no longer electrostatic attraction and the material will cease to absorb ions. Conversely, if the material being neutralized is charged negative, it will absorb the positive ions being generated by the neutralizer and repel the negative ions. Again, once neutralization is accomplished, the material will no longer attract ions.

ELECTROSTATIC FIELD

To control static electricity in high speed converting, it I extremely important to understand the electrostatic field present on non-conductors charged with static electricity and its effect. Basically, this electrostatic field is mother nature's antenna, sending a signal to the world that the material is unbalanced and is seeking anything which will neutralize it. Therefore, if a grounded roller is present or a grounded member of any machine is present, the electrostatic field will attract the non-conductor to the surface. When this happens, machines can jam, webs can wrap around conductive rollers, and create general havoc. Likewise, the same electrostatic field sends the signal to the ions being generated by any static neutralizing system, causing ions of opposite polarity to be attracted to the surface.

It is important to appreciate that material must be placed in "free space" in order for a static neutralizers to do its job. Likewise, the electrostatic field also causes the non-contacting static locator meters to operate. This electrostatic field sets up the energy necessary to unbalance the electronic circuit and hence the field strength can be measured on the static meters.

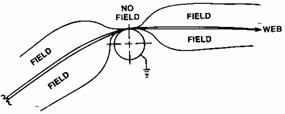

If the non-conductive, charged material is placed against any surface, the electrostatic field is collapsed and, hence, the material appears neutral. For example, as the web of charges material passes over a grounded roller, the electrostatic field will look as follows:

As can be seen from the above sketch, placing the static neutralizing bar over top of the grounded roller, will do no good in controlling static electricity, because there is no electrostatic field present at that location. The static neutralizing bars must be placed against moving webs and sheets so that there is no grounded backing present when utilizing static neutralizers.

Finally, unless the material is extremely thick, it is only necessary

to apply static neutralizers on one surface only. This is due to

the fact that the electrostatic field present on both surfaces is

a mirror image and is identical in both strength and polarity.

It must also be understood that when neutralizing multi-webs or multi-sheets, a static neutralizer will only neutralize both outside surfaces. Hence, as in the case of sheeting, if four stacked webs are processed at one time, four sheets are converted simultaneously. The application of static neutralizers on the "clip", consisting of four sheets, will only neutralize the static electricity on both outside surfaces and will not neutralize the static which is present between the multi-layers.

Recognizing this phenomenon, it can easily be seen that controlling static electricity in high speed sheeting can be accomplished, due to the fact that each "clip" must go into a pile easily and hence the converting is accomplished. However, the "locked in" static electricity that is present in between the sheets of the "clip" will cause problems in the future. For example, when the sheets of converted paper reach the user, a printer, for example, it will be difficult to get single sheets to enter his printing press. In this case, the printer must also utilize static control equipment at the proper location.

HIGH SPEED CONVERTING

Keeping in mind that the conventional, alternating current, neutralizing systems can be "over-run" when running at extremely high speeds because we are changing polarities every 1/120 of a second. It is important to recognize that if the speed of the material being processed to a point above about 800-1000 feet per minute, a condition will arise when, for example, positively charges material passes under the static neutralizer during the positive ionization generating cycle. At this point in time no neutralization takes place. Since like charges repel each other, the same polarity of ions as the static charge on the material will cause a repulsion or the ions. That is why no neutralization occurs. The faster the speed goes above 600 feet a minute, the wider the "striping" occurs. This means that as the speed increases further, there will be portions of the above phenomenon. Increasing the speed to, say. 1200 feet a minute will cause the "stripe effect" to increase in size. A larger portion of the processed material will remain charged, even though it is passed under a static neutralizer.

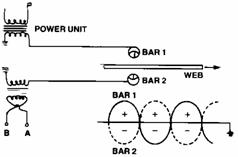

When operating at speeds above 800 feet per minute, it is necessary to use what is commonly known as dual-phasing. Normally, static neutralizing bars are placed on one side of the web. To overcome the "striping", phasing can be accomplished by utilizing two static neutralizing systems as per the following diagram.

As can be seen from the above, the primary side of the transformer, labeled A and B can be reversed so that the top static neutralizing bar is generating positive ions, while the bottom static neutralizing bar is making negative ions. Therefore, there occurs a better flow of both polarities, ionization during the AC cycling of these systems. Yet the stripe effect may occur at very high speeds because of the pulsing ionization out put of alternating current.

The next step up the cost / performance ladder is to go to a resistance coupled static bar. This technology offers better static control performance especially at a greater distance and higher web speeds using conventional AC power suppliers.

Finally, the best way to manage controlling static electricity in high speed operations is to utilize a double DC unit. Basically, a double DC unit is two static neutralizing bars, each connected to its' own DC source. Since direct current only goes in one direction, one row of ionizing points places negative ions in the area at steady state and the second row of ionizing points generates positive ions and hence, both polarities are steady. This equipment will serve to extremely high speeds.

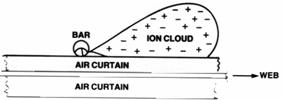

Another factor to consider when utilizing at high speed is that a high speed moving web will always carry an air curtain with it, hence, steps must be taken to overcome this phenomenon.

Basically, the problem with this air current is the fact that it becomes difficult for the ions to penetrate this air current and, hence, the ions will travel across the top of the web and on top of this air curtain as follows:

To overcome this, it is necessary to either "peel" this air current from the area by utilizing a non-conductive shield as per the following sketch:

A second alternate is to use air boost on the static neutralizing system so that the compressed air can pass through the use of high pressure air, penetrate this air curtain, causing the ions to reach the surface of the highly charged, moving web.

SUMMARY

(A) Static electricity can only be neutralized and not eliminated. To eliminate static electricity, something physically has to be done to the conductivity in the material being processed. Therefore, if you are having problems with static electricity at the delivery end of your equipment, it will serve no purpose to add static neutralizers at the feed end of this equipment. The static neutralizing system must be applied directly ahead of the problem in any processing equipment.

(B) Mechanically grounding a non-conductor, such as a ground wire floating across the top of the web, will not neutralize static electricity, due to the fact that electricity cannot flow in insulators and hence, the term "static electricity".

(C) Static neutralizing equipment must be applied to the material being neutralized only in locations where the material is in "free space" and not against any grounded backing surface.

(D) Alternating current static neutralizers are only effective up to running speeds about 600 feet per minute. Beyond that speed, "striping" will take effect whereby a certain stripe area is neutralized and the next area is charged. Above speeds of 600 feet per minute, phase shifting must be applied or a double DC system must be utilized.