Dust Control Web Cleaning

in Paper applications

Dust Control is a serious problem across the paper manufacturing and paper converting industries. The paper dust poses fire, maintenance and operator comfort issues on the machines and throughout the plant.

Most paper manufacturers use area hoods connected to a vacuum system to collect the dust filled air at various locations inside and around a machine. These systems rely on ventilating the dust filled air from the high dust areas. The performance of these systems are limited for several reasons:

- The area hood systems waits for the dust to get into the air at random location along the web path before trying to deal with it.

- The make up air in the room may also have dust in it reducing the effectiveness of the ventilation concept.

- The area hood systems have to be far from the web so it does not sucked up the web.

- A substantial amount of vacuum is required to operate enough area hoods to cover a larger converting or paper machine.

- The area hoods are a reactive approach which do not deal with the root cause of the problem which is keeping the dust from getting into the air in the first place.

The Issues:

A large percentage of the paper dust is usually in the roll and a smaller percentage comes from fibers broken as the web goes over rollers in a machine. The dust from the the roll will come off the web at various locations along the web path. If the dust on the roll can be collected early in the processes this will dramatically reduce the amount of paper dust in the air and in and around the machine. This will leave just spot pick ups in locations where dust is generated by breaking fibers along the web path.

The criteria for such a system would be: 1) able to operate at various web widths and speeds; 2) not interfere with current operations and cause web breaks; 3) not require more (and preferably less) vacuum than the current system.

A new approach:

ElectroStatics has developed a new approach for managing dust control on the paper making and converting machines by drawing on its long experience of designing and building web cleaners.

ElectroStatics Dust Collection Systems utilizes an ionized air boost to neutralize static electricity. This eliminates the electrostatic field; thus polarization, releasing contaminants for instant vacuum cleaning in one highly efficient action. It thoroughly neutralizes and cleans any web in a single operation, the first time through. Removing the dust directly from the web, before it has the opportunity to get airborne, dramatically improves the overall efficiency of the dust collection system compared to area hoods while using the same or less vacuum per location and usually much less vacuum for the whole machine.

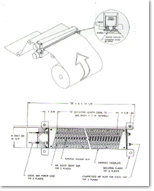

The non contacting web cleaning system, with its patented grooved face plate, is designed to operate in very close proximity without damaging the high speed thin web. This allows the ionization, air boost and vacuum to work together more to more efficiently pickup the paper dust.

Wide web style web cleaners are available to any width web. For systems less than 30" see our narrow web design of webcleaners

Click here to send ElectroStatics a Request of Quote on a webcleaning system.

ElectroStatics now offers financing for its cleaning systems. Contact us to find out more information

ElectroStatics dust control system shown here with differ vacuum ports.